Introduction

Evaporative cooling is one of the most ancient method of cooling. It is best illustrated by the chilling effect you feel when you get out of a swimming pool and a breeze blows across your body. This chilling effect is covered due to evaporation process of water drying quickly from your body.

Basis of Design…. Why Adiabatic ?

Please note that the Air cooled Fluid cooler totally depend on dry bulb temperature of air which is generally between 5 to 17°C higher than the wet bulb temperature (depending from location to location). Traditionally, large heat reference application made use of Cooling Tower, but due to problem with corrosion, maintenance and now acute shortage of water made the industry to move towards dry bulb heating system i.e. Air cooled Fluid Cooler.

The Wet Bulb efficiency advantages with conventional cooling towers applicable only during the period of high ambient temperature, but wet system are designed to operate all year around even at low ambient conditions, hence the cost of water and maintenance increases unnecessarily.

These disadvantages of conventional system can be over carried by eliminating the need for all years round water operation by means of introducing Adiabatic cooling system with Air-cooled Fluid Coolers, which operate only during peak summer and that also for limited hours.

Working Principle

Based on the low temperature requirement with Air Cooled system , we introduced into market the latest technology of Unitized Cooling system in which the outlet temperature can be maintained much below the ambient even in peak summers.

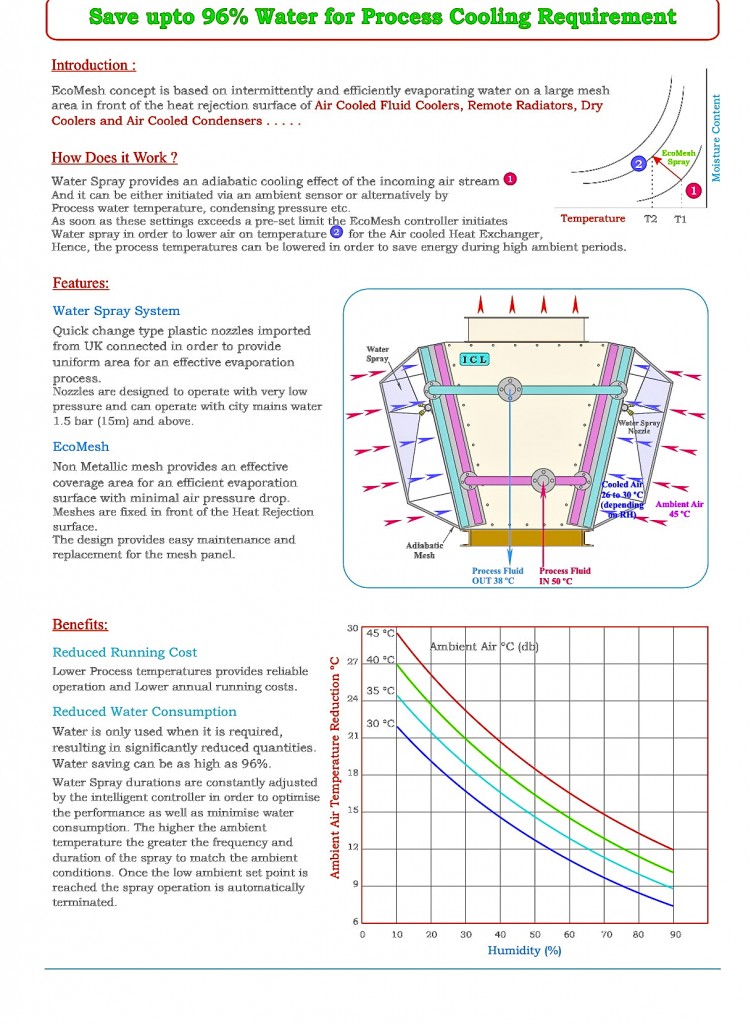

The concept works on the principle that hot water coming out enters into our Air-cooled fluid cooler. An imported Ecomesh surrounds throughout the coils. Ecomesh concept is based on intermittently and efficiently evaporating water on a large mesh area front of heat rejection surface. It acts as a Evaporative Air inlet cooling unit for our Air cooled fluid cooler. The ecomesh uses non-metallic wired mesh panels, and the adiabatic cooling effect is created via an intermittent water spray over the wired mesh surface (not on the ACFC). This reduces the Air pressure drop significantly. Water rapidly and efficiently evaporates on a large mesh surface. Kindly note that the water is sprayed on the Ecomesh and not on our coils. This spray on mesh creates an area of 90% saturated working area before the coil. In this case the DB is nearly 2 to 3 °C above WB temperature.

The operation is automatic and is initiated by using an ambient sensor. As soon as the ambient Dry bulb shall exceed a pre set level, an adiabatic i.e. air cooling by water evaporation, can be initiated to lower the air on temperature for the Air cooled fluid coolers. The adiabatic cooling process introduces water into the incoming air stream. The water rapidly evaporates and the hidden energy of water provides cooler air downstream. This will be 10-15°C colder than the ambient air, depending upon R.H. The system not only saves energy but also saves water as the water is only used when required.

A software driven controller initiates the water spray operation based on the ambient temperature. As soon as the water spray request is received the controller initiates an in- line solenoid valve to start the adiabatic cooling process. The controller follows the ambient profile and adjusts the quantity & duration of spray to ensure optimum cooling effect with minimum water consumption. Once the low ambient set point is reached the spray operation automatically terminates.

If the main water pressure available is 25 to 35 PSIG , the nozzle spray line can be connected directly from main water supply. But if the pressure is less than a custom built pressurized pump has to be installed for pressurizing the water and maintaining a effective spray in the nozzles.

On the basis of this concept it has been worked out that the water consumption in this is only 8% as compared to the conventional cooling system (Save 92% water).

Add Comment