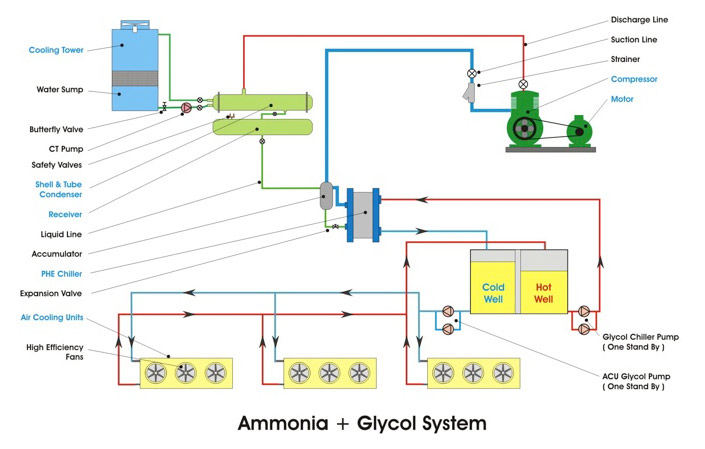

Water foods has wide experience in the design and installation of Cold Store cooling employing a glycol “Secondary Refrigerant Systems”

Glycol, or secondary regfrigerant systems for cold rooms or cold stores, feature an outdoor glycol chiller interconnected to the indoor blast coolers with mild or stainless steel pipework through which low temperature food safe glycol is circulated.

Glycol Systems for cold stores have many benefits over a traditional Direct Expansion System. A simple and easy to install pipework system with no expensive refrigeration skills required:

- A significant reduction in system refrigerant volumes

- A simple and easy to install pipework system with no expensive refrigeration skills required

- No leaking of refrigerants into the cold space

- Smaller quantities of refrigerants held in the outdoor chillers

- Easier conformance with F Gas regulations

- Lower life time service and maintenance costs

A system which can easily be extended, expanded or repositioned.

Low temperature glycol chillers can be applied for process cooling or as part of a secondary refrigerant system for chilled and cold storage applications. Packaged chillers can be supplied in a range of capacities with the capability to provide glycol at temperatures from +5°C to as low as minus 12°C.

Features include:

- Screw compressors.

- Plate or shell and tube type evaporators.

- Air or water cooled condensers.

- Intuitive multi functional micro processor controller.

- Integral glycol circulating pumps.

- Hot & Cold Well.

Add Comment